Traditionally, manufacturers have made products with little requirement to consider would happen to their materials after their primary life. The drive towards a Circular Economy means the development of a sustainable materials chain which has all the advantages of modern highly functional materials in their primary and secondary uses but combines it with real end-of-life options so materials can be reused, recycled or treated organically. This conserves the worlds resources as well as reducing plastic pollution in the environment.

Accelerating the transition to the Circular Economy

What is the circular economy?

How does Hydropol™ enable circularity?

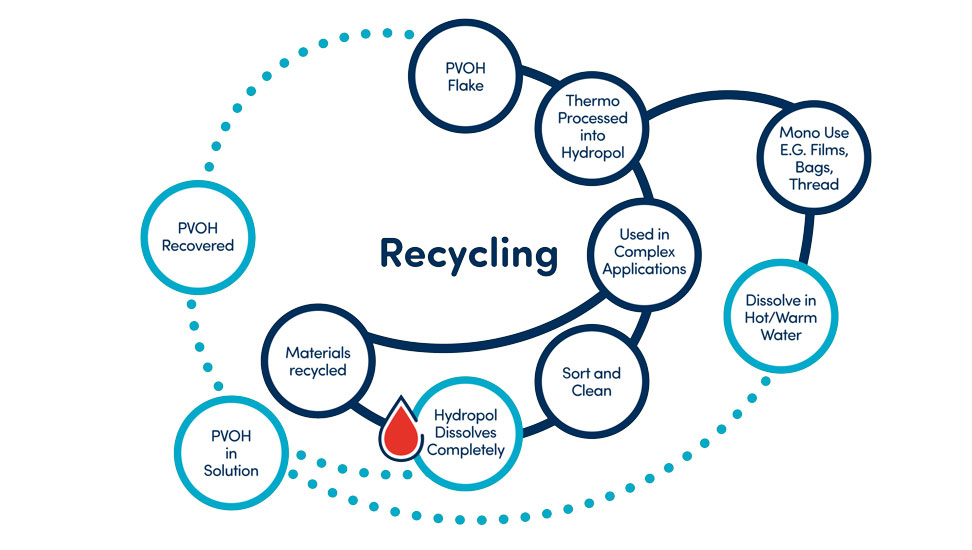

Aquapak believes in a world where recycling is technically and economically feasible even for complex material constructions. Hydropol™ is an enabling technology, as it can be used in conjunction with both existing and new materials to design applications and packaging that retain its primary functionality but has additional properties allowing it to meet circular economy goals.

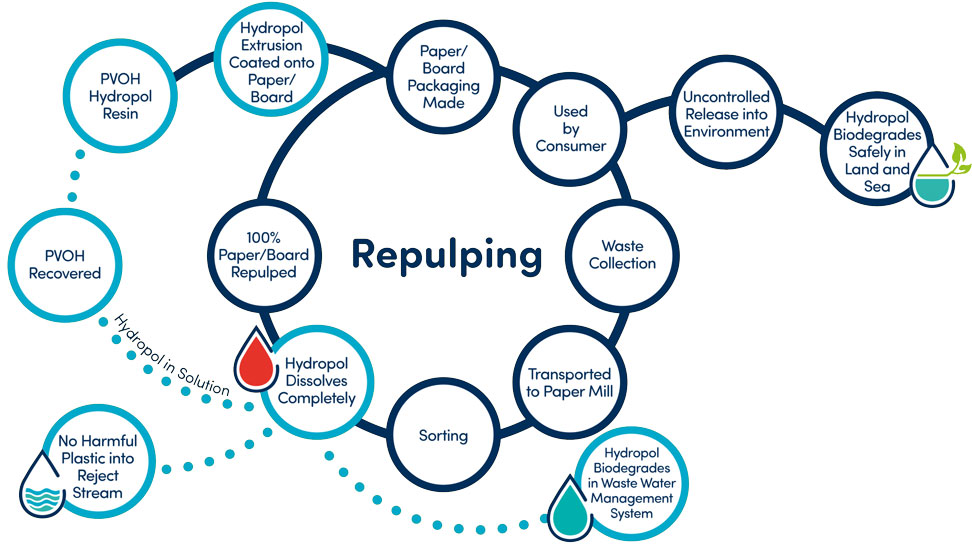

Hydropol’s controlled solubility means that it enables the separation of complex materials within the recycling processes:

For example, in paper mills, Hydropol™ has been proven to wash off in the repulping process, allowing 100% of paper fibers to be recycled with no negative effects to the paper mill.

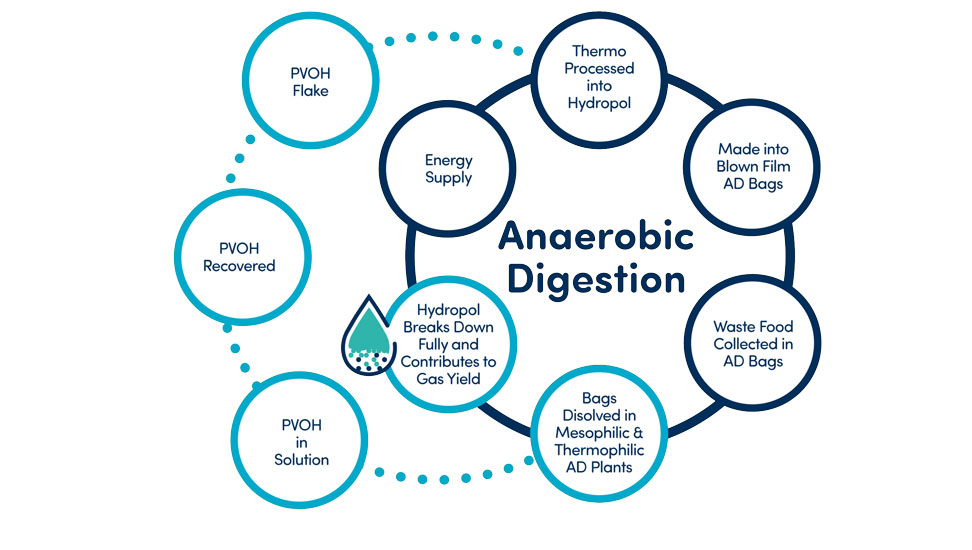

Hydropol™ is also compatible with Anaerobic Digestion (AD) systems, which convert food and other organic waste into bio-gas which can then be used for energy generation as well as producing biodigestate, a valuable fertilizer. Nearly all AD systems require post pasteurization to kill pathogens and this process will breakdown any residual Hydropol™ material which hasn’t already been digested in the AD cycle time:

Hydropol™ is non-toxic and marine-safe and because of its inherent biodegradability in different environmental conditions offers a safer alternative to conventional polluting plastics.